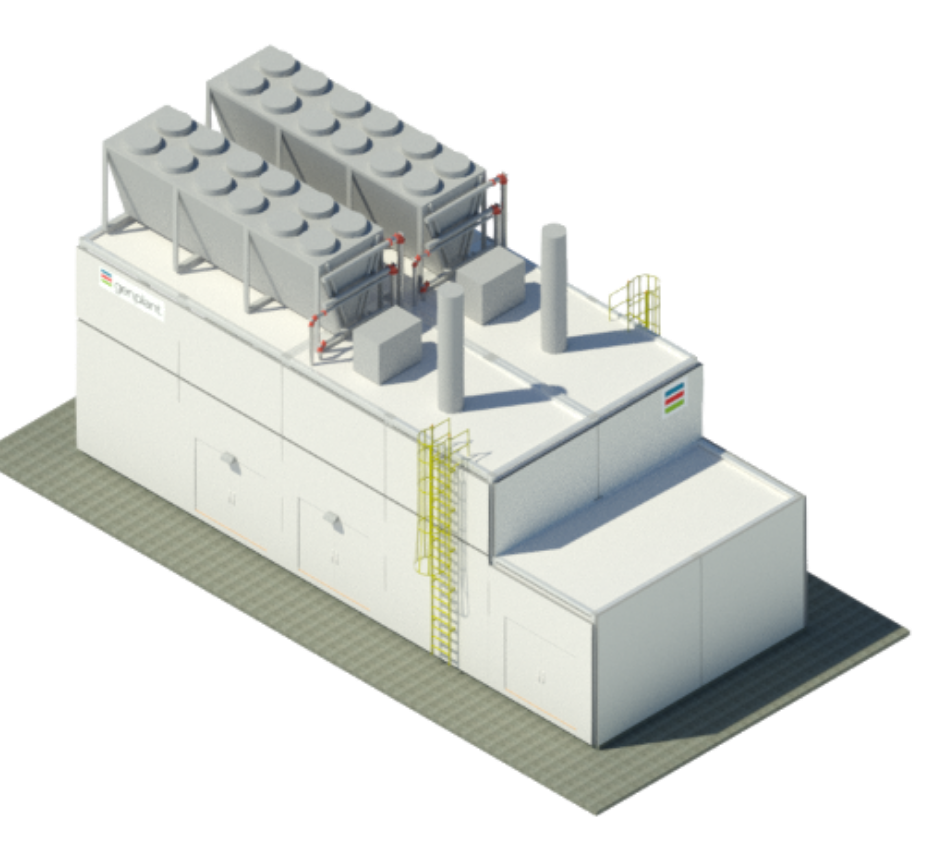

Combined Heat and Power (CHP) Plant

When a leading industrial gas manufacturer was considering a new production facility, they contacted Genplant to design an energy plant solution that would meet their phased growth needs and provide more cost-effective, reliable electricity to support new production of liquid oxygen, nitrogen and CO2.

Genplant designed a natural gas-fueled CHP plant that delivers up to 1.5 MW of electricity and produces both steam and hot water. The CO2 from the plant's exhaust is recovered and converted into beverage-quality CO2.

Because CHP plant operates independently from the utility electric grid, it has built-in redundancy for electricity production and can operate on diesel and/or propane as an alternative to natural gas.

As part of our scope of services, Genplant designed the LNG station and supplied all CHP-related equipment.

Client Objectives:

- Design an energy solution for new production facility

- Implement a solution to account for company's phased growth

- Reduce energy costs

- Improve energy reliability